Diamond saw blades work best when cutting wet. The water will prevent the blade from overheating and distorting in shape, it reduce harmful dust created by cutting, and will remove the slurry from the cut. Diamond cannot withstand the forces involved at the elevated temperatures of dry cutting ceramic and abrasive materials, and will be subject to rapid tool wear and possible failure. Blade life is greatly extended by wet cutting. However, many saw blades are designed to operate either wet or dry.

Dry saw blade should be limited to situations where water isn’t available easily or used in electrical saws machine.

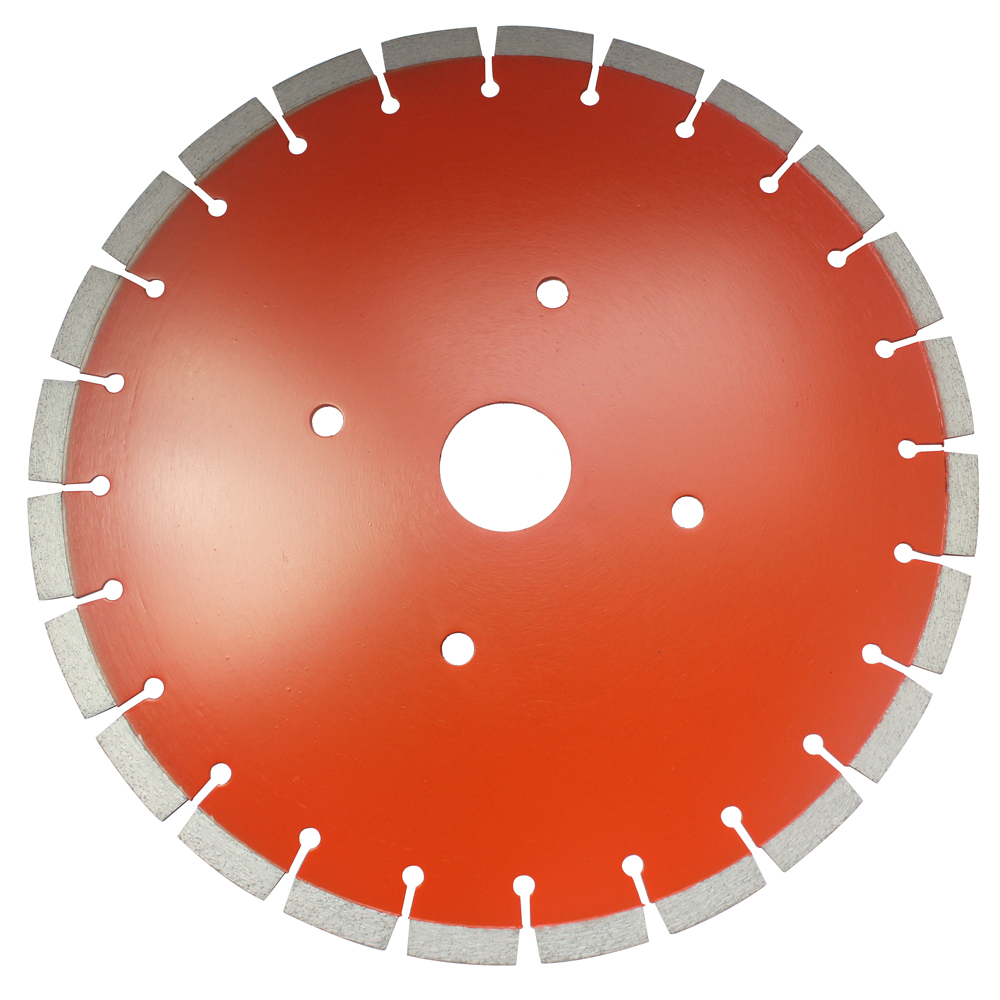

When doing dry cutting, the blade should be allowed to cool off periodically. Cooling can be increased by allowing the blade to spin freely out of the cut. Cut this way for a few minutes, then you should start to see the cutting surface get some shape back, this causes the bond to wear away and expose the diamonds which do all the cutting. This allows cool air to pass between the segments.

Dry diamond cutting is dangerous for persons unfamiliar with the risks and process.