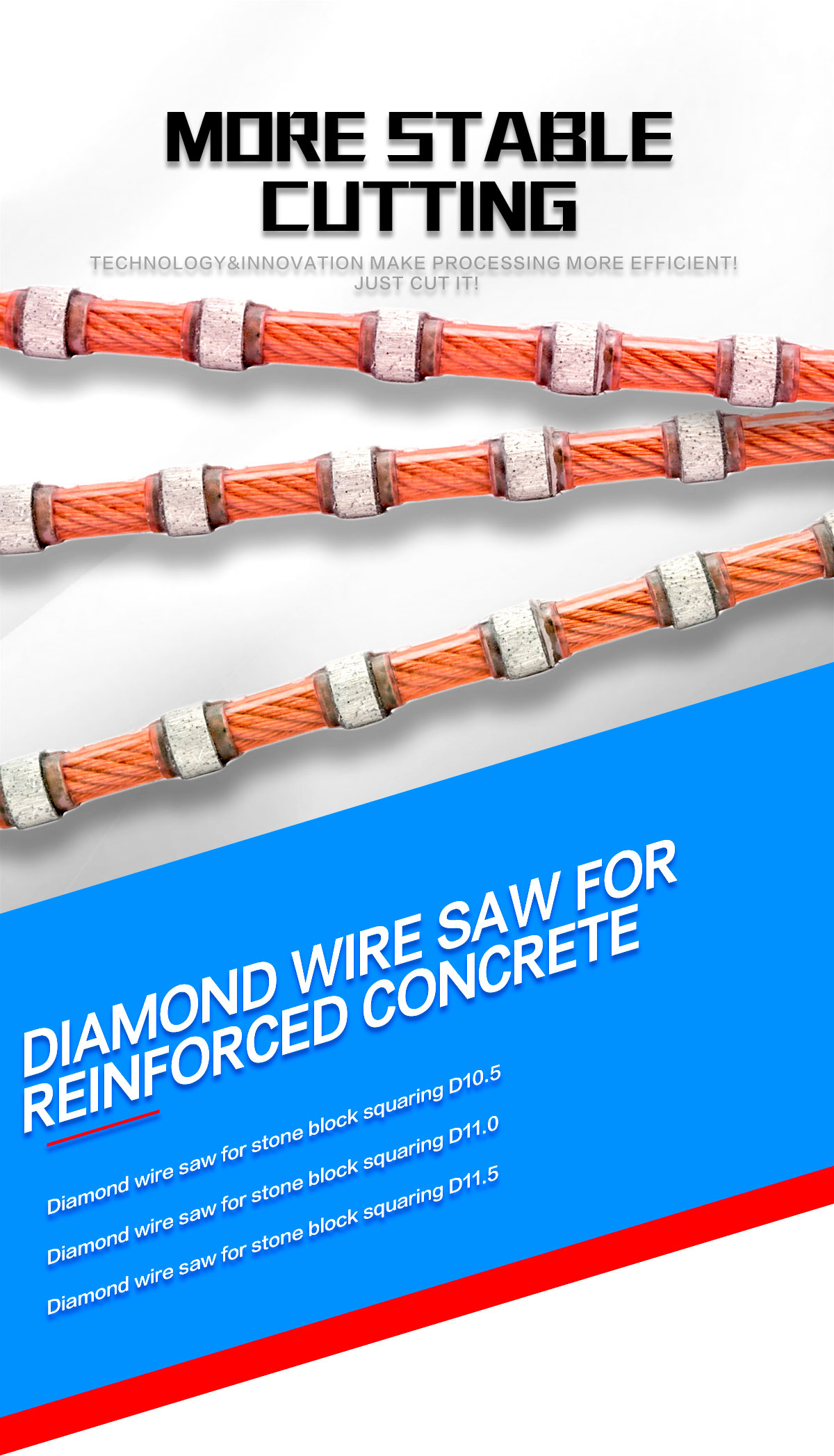

The diamond wire saw is used for special-shaped block processing:

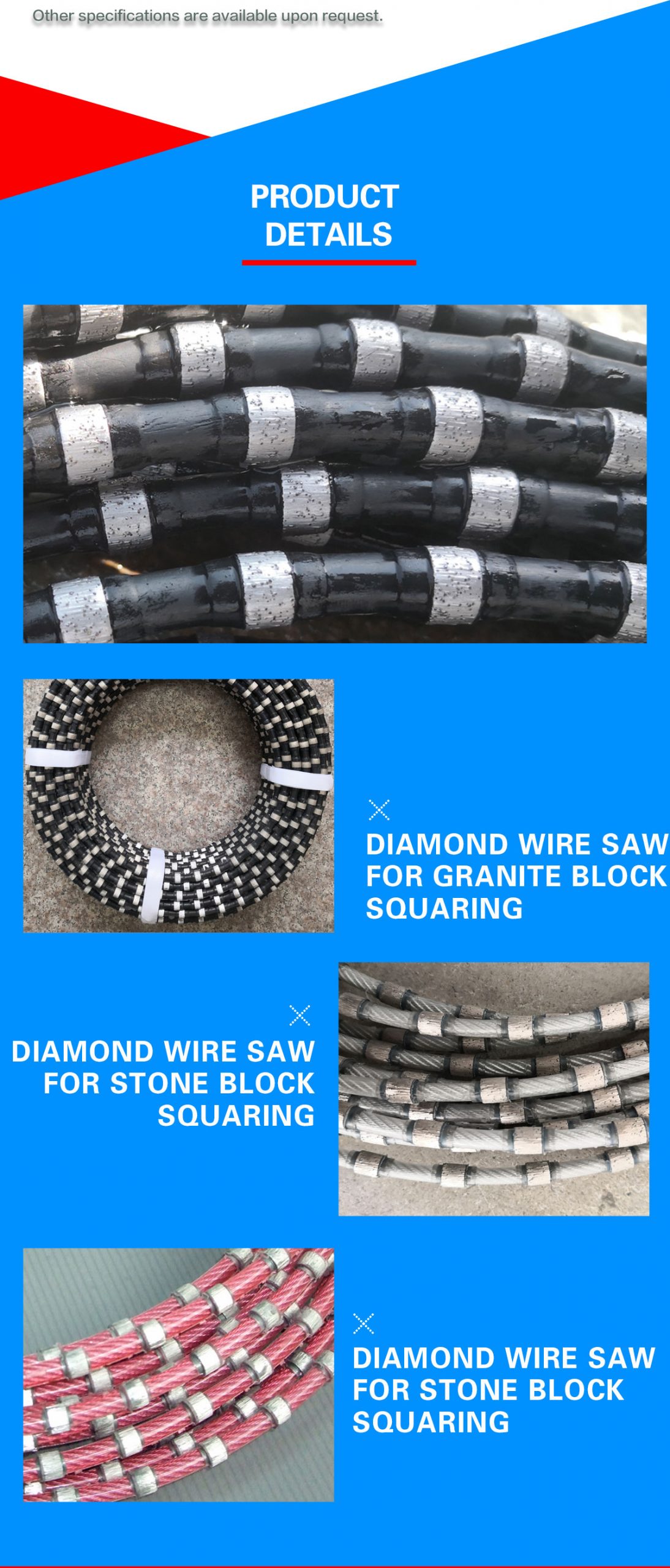

Three essential components for diamond wire saw are as followed:

- Steel cable with diefferent diameter depending on the application

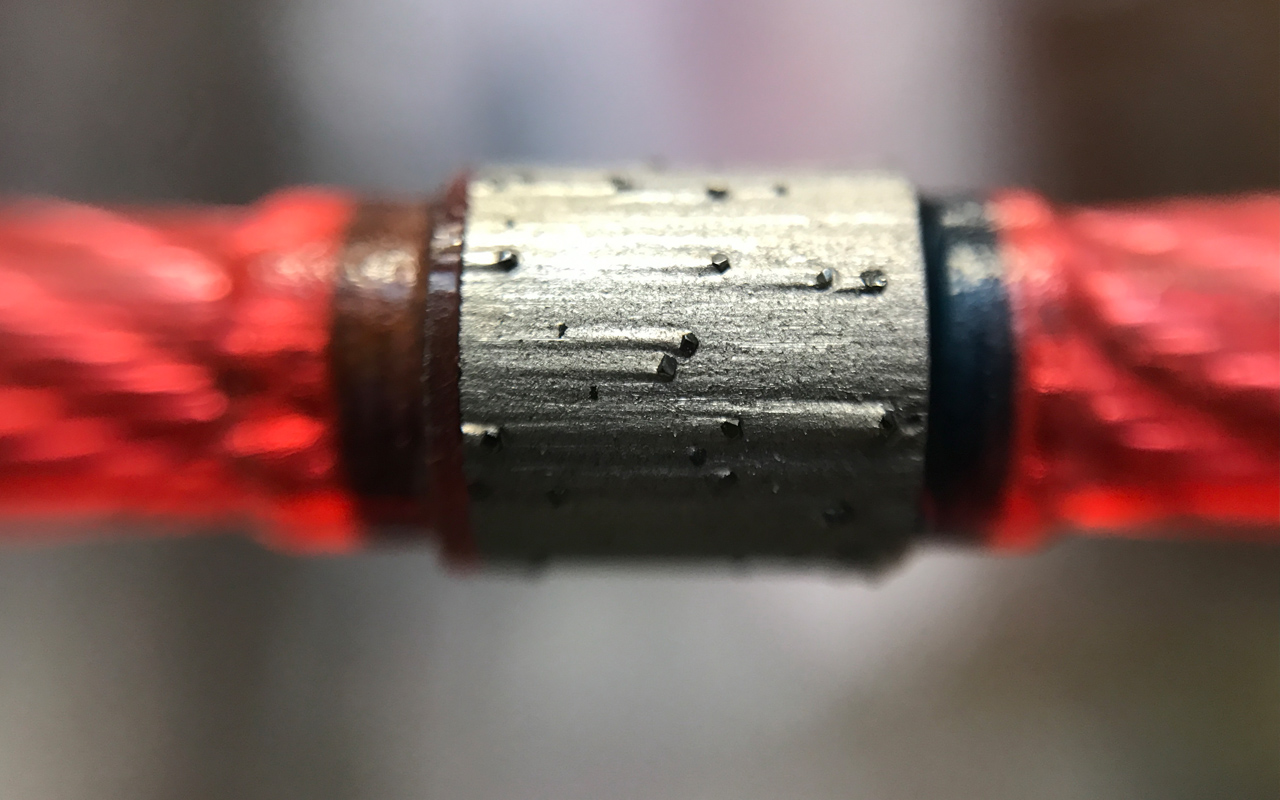

- Sintered diamond beads.

- Fixed method: springs, rubber or plastic. Protects the steel cable because of stone abrasive, and also sbsorbs the energy of the cutting friction of the beads against the stone.

Product features:

1.The use of diamond wire for stone profilling,with narrow kerf width and high quality cable insure less breakage and good tension,bring beter performance in tough environment.

2. This wire saw works in low noise,safe and eco-friendly.

3. High effection, low cost, low waste

4. Cutting smooth and process accurate

5. Safe and environmental protection.

6. The profile wire saw can process a variety of special-shaped stones, and the cutting angle and orientation can be adjusted arbitrarily.

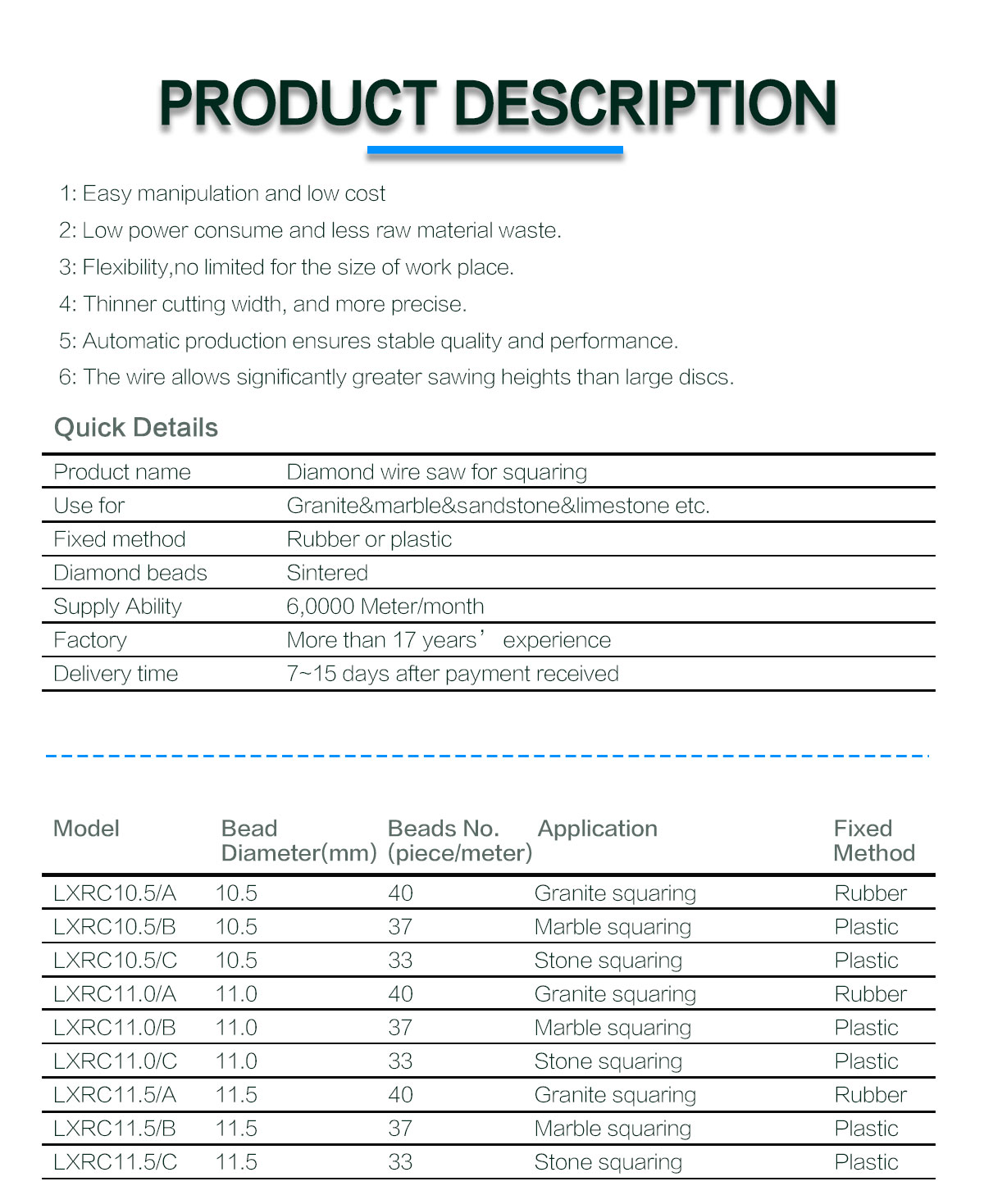

| Application | Coating | Diameter(mm) | Beads No. | Hardness | Wire Speed | Cutting | Life |

| Granite squaring | Plastic | 10.5 | 33 | Soft | 28-30 | 1.5-3.0 | 15-25 |

| Granite squaring | Plastic | 11.0 | 37 | Medium | 23-26 | 1.0-2.5 | 12-15 |

| Granite squaring | Rubber | 11.5 | 40 | Hard | 20-25 | 0.5-1.0 | 8-12 |

| Marble squaring | Plastic | 10.5 | 33 | Soft | 30-35 | 3-6 | 30-40 |

| Marble squaring | Plastic | 11.0 | 37 | Medium | 25-28 | 2-4 | 25-30 |

| Marble squaring | Rubber | 11.5 | 40 | Hard | 23-25 | 1-2 | 20-25 |

Reliable cutting and can change the cutting technology according to the stone types.

A large number of exports to Eastern Europe, North America, South America, the Middle East, Australia and other overseas markets, product quality has been recognized by overseas customers.