Diamond segments for sandstone block & slab cutting

Sandstone segment is used for cutting sandstone, . The sandstone material is soft and easy to break the slab edge. Therefore, the sharpness requirements are very high. The sandstone segment produced by Linsing diamond segments is extremely acceptable, and our products can easily cut the Australian and Indian sandstone. Not only that, in terms of price and style, K-shape and M-shape segments also have strong cutting performance for special sandstones.

Linsing diamond segments features:

1. The segments has good sharpness and high efficiency at the process of cutting, meanwhile, it has a long lifespan.

2. Good cutting result: Smooth cutting, flat surface and even size.

3. Stable cutting, narrow cutting gap, stone waste reduction.

4. M-shape segment is easy for diamond opening.

Among the natural stones, there is a kind of stone called sandstone. It is natural sand and gravel and stone powder that pass through the water and continuously precipitate to form a stable structure. Later, through the movement of the earth’s crust, the river is called a mountain range, which forms the sandstone we see now Because it has been in water for a long time during the formation process, the sandstone composition also contains iron oxide, clay and other ingredients. Of course, most of it is still gravel. The biggest advantage of this material is that it is not afraid of water, so it is widely used for exterior walls and decorations. Walls, outdoor floors, stone carvings, etc.

Sandstone is one of the most difficult materials in the world to process. The first manifestation is the large hardness span, from soft sandstone to medium-hard sandstone, from medium-hard to super-hard sandstone. The hardness of various sandstones varies greatly. The second performance is in abrasiveness. Soft sandstone has high abrasiveness, while hard sandstone has low abrasiveness. The third manifestation is the instability of the structure. Some sandstones require high cutting speed. Once the speed is not enough, the unstable cutting will cause the sandstone to collapse and fracture. So why can Linsing’s segment cut sandstone well? In general, Linsing Diamond Tools Co., Ltd. solved the following three problems, and subsequently sandstone segment gradually became the mainstream product in the market.

Solve the problem of cutting super-hard sandstone: At present, there are very few segment categories for sandstone cutting on the market, especially some super-hard sandstone. Due to the small amount of such sandstone and the small amount of mining, many manufacturers will not specifically research and develop this In 2015, Linsing set up a sandstone segment design team to specialize in super-hard sandstone segment products. After 3 years of continuous testing and improvement, only Linsing diamond tools can make super-hard sandstone segments. Other manufacturers’ sandstone Either the segment cannot be cut, or the life is insufficient, neither can reach the normal sawing level.

Solve the problem of strong versatility: There are not many sandstone products. If you want to develop different segments for sandstones of different hardness, such as medium-soft, medium-hard, hard, and super-hard, it will take more manpower. The expectations of sandstone segments are not high, so the research and development of through-cut sandstone segments has become inevitable. Linsing has envisaged combining the formula of super-hard sandstone segment with medium-hard sandstone segment since 2017, and wants to deploy a set of segment products that can be cut through. After more than 2 years of testing, in mid-2019, we designed two A set of sandstone formulas, LXSY-1026 and LXSY-3035, are life-type sandstone segments and efficiency-type sandstone segments, respectively. The current-cutting life of life-type sandstone segments is much longer than that of other manufacturers’ sandstone segments.

The third problem that Linsing solves is the problem of fast cutting, because although the sandstone material is stable, the quartz sand still exists in granular form after all, especially in the face of medium-soft or soft sandstone materials. The instability will cause the saw blade to shake will cut the sandstone. The best way to increase the cutting performance of the segment and improve its stability is to increase its sharpness. Since 2019, Linsing engineers have been adjusting the sharpness of sandstone segments. Currently, our sandstone segments It can be sharpened at a very fast speed. In the case of high cutting speed, the cutting is very stable. What’s more, this kind of processing will not reduce the life of the segment. This is derived from the Linsing segment engineers’ understanding of product performance. Grasp and understand the characteristics of diamond segment.

Of course, there is no limit to learning. Linsing’s sandstone segment is still being debugged. If the cost can be reduced, then our products will have more advantages. Linsingdiamond segment: the most cost-effective stone processing tool!

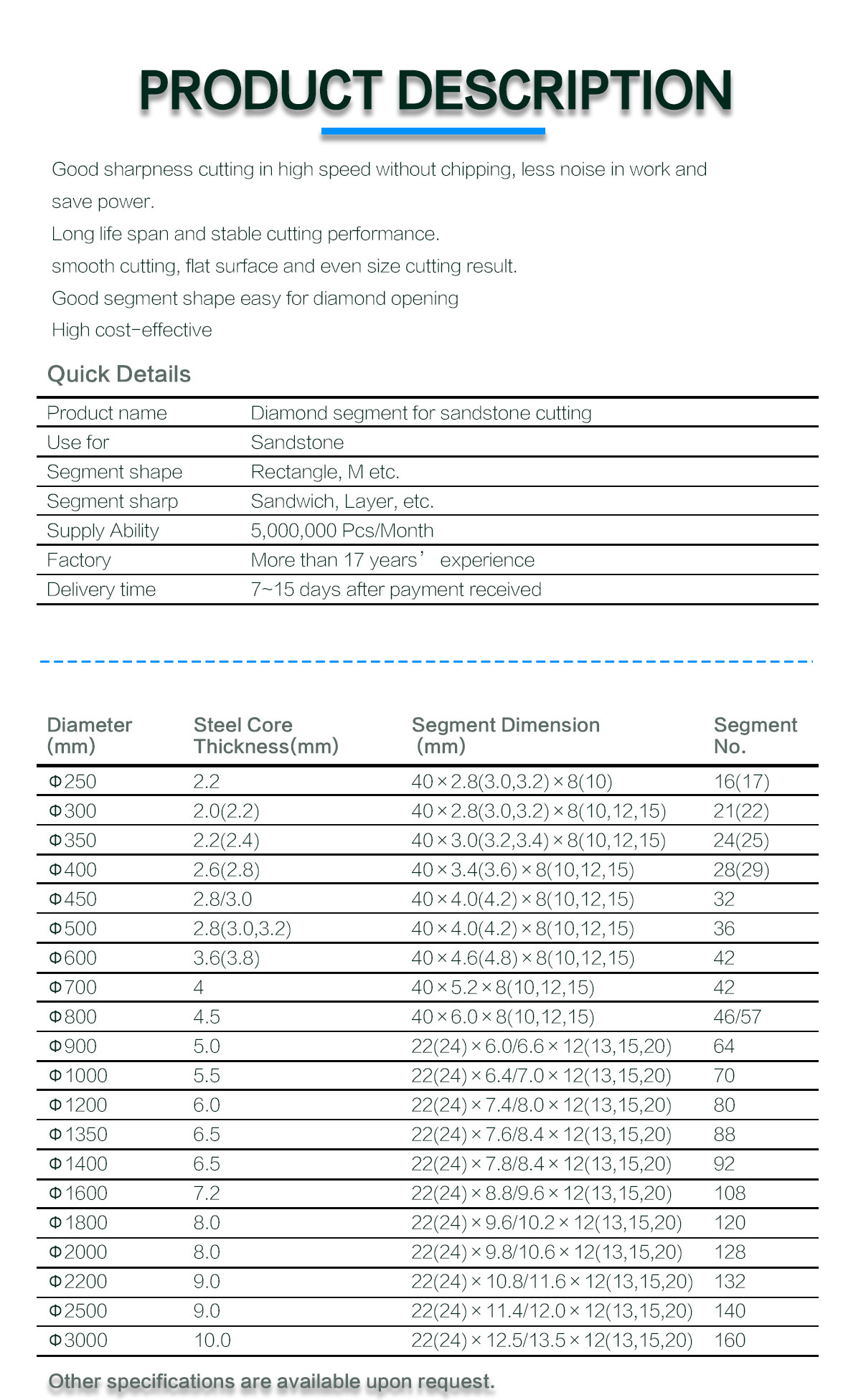

Diamond segments for 300-800mm saw blade:

| Diameter | Diameter | Core Thickness (mm) | No. of Teeth | |||

| mm | inch | Length | Thickness | Height | ||

| 300 | 12″ | 2.0/2.2 | 40 | 2.8/3.0 | 8/10/12/15 | 21 |

| 350 | 14″ | 2.2/2.4 | 40 | 3.0/3.2 | 8/10/12/15 | 24 |

| 400 | 16″ | 2.6/2.8 | 40 | 3.4/3.6 | 8/10/12/15 | 28 |

| 450 | 18″ | 2.8/3.0 | 40 | 4.0/4.2 | 8/10/12/15 | 32 |

| 500 | 20″ | 2.8/3.0 | 40 | 4.0/4.2 | 8/10/12/15 | 36 |

| 600 | 24″ | 3.6 | 40 | 4.6 | 8/10/12/15 | 42 |

| 700 | 28″ | 4 | 40 | 5.2 | 8/10/12/15 | 42 |

| 800 | 32″ | 4.5 | 40 | 6 | 8/10/12/15 | 46/57 |

Diamond segments for 900-3500mm single/multi diamond blades

| Diameter | Diameter | Core Thickness (mm) | No. of Teeth | |||

| mm | inch | Length | Thickness | Height | ||

| 900 | 36″ | 5 | 22/24 | 6.0/6.6 | 12/13/15 | 64 |

| 1000 | 40″ | 5.5 | 22/24 | 6.4/7.0 | 12/13/15 | 70 |

| 1200 | 48″ | 6 | 22/24 | 7.4/8.0 | 12/13/15 | 80 |

| 1400 | 55″ | 6.5 | 22/24 | 7.8/8.4 | 12/13/15 | 92 |

| 1600 | 64″ | 7.2 | 22/24 | 8.4/9.0 | 12/13/15 | 108 |

| 1800 | 72″ | 8 | 22/24 | 9.2/9.8 | 12/13/15/20 | 120 |

| 2000 | 80″ | 8 | 22/24 | 9.5/10.5 | 12/13/15/20 | 128 |

| 2200 | 88″ | 9 | 22/24 | 10.5/11.5 | 12/13/15/20 | 132 |

| 2500 | 110″ | 9 | 22/24 | 11.5/12.5 | 12/13/15/20 | 140 |

| 3000 | 120″ | 10 | 22/24 | 12.5/13.5 | 12/13/15/20 | 160 |

| 3500 | 140″ | 10 | 22/24 | 13.5/14.5 | 12/13/15/20 | 180 |